Durga Varaprasad

MASTERS IN TOOL DESIGN

Skills Acquired at Skill-Lync :

- MATLAB-BASICS

- HYPER-MESH

- STRUCTURAL-MESHING

- SHEET-METAL-MESHING

- FEA

- RADIOSS

- CRASH-WORTHINESS

- DESIGN

Introduction

32 Projects

Week 4-1D Element Creation Challenge

Objective: To Mesh the Given component with size of 5 and create 1D element with given cross sections and DOF. a. Rod element:- Translational DOF should be Constrained with RBE2 link Cross-Section: BOX- Dimension a= 12 mm …

06 Mar 2021 05:48 PM IST

Week 8-3D Tetra Meshing Challenge

OBJECTIVE:1.Creating Tetramesh for a given housing model by 2D TO 3D conversion method 2.Creating Tetramesh for a given component by volume/direct tetra mesh method 3.Creating Tetramesh for a given…

16 May 2021 05:18 PM IST

Week 9-Creation of 1D Connectors Challenge

OBJECTIVE: To mesh the given geometry. Provided below are the quality parameters that you have to follow. Target Element size - 5 Units S.N Quality Criteria Value 1 Aspect Ratio 5 2 Skewness 45 3 Warping 15 4 Taper 0.5 5 Min. Length 2 Units 6 Max. Length 8 Units 7 Min…

31 May 2021 03:27 PM IST

Week 6-Meshing of Hood Challenge

OBJECTIVE:To mesh the given component with Target element length 5mm.with minimum tria concentarion and following given quality criteria CAD Model: Inner extract Outer Extract: Hinge Reinforcement Extract: Latch Reinforcement Extract: Procedure: we need to work on components individually first we need to import…

18 Jun 2021 07:19 AM IST

Week 12:Project 2-Meshing of Rear Wheel Holder challenge

Objective: extract Midsurface and Follow the below-mentioned quality criteria, mesh the component given below and assign thickness: Target Element Length = 5 Units S.N Quality Criteria Value 1 Aspect Ratio 5 2 Skewness 45 3 Warping 15 4 Taper 0.5 5 Min. Length 2 Units 6 Max. Length…

25 Jun 2021 06:36 AM IST

Week 12:Project-1-Meshing of Door Inner Panel Challenge

MESHING THE PLASTIC COMPONENT OF A CAR SIDE DOOR USING HYPERMESH Aim: To extract the mid surface of the given plastic component and mesh the model according to the given quality criteria and apply thickness. Procedure:In order to accomplish the above objective we need to follow following steps: Import the CAD model into…

02 Jul 2021 12:04 PM IST

Assignment 1-2D Meshing Challenge

OBJECTIVE: To Carry out the geometry cleanup operation on the given 3 files. Practice Clip Repair Mounting Bracket There should not be any free edges, convert all of them into refine geometry. need to perform these operations on the model Clean the geometry. Extract midsurface. Clean midsurface geometry.…

14 Jul 2021 05:10 PM IST

Assignment 2-RADIOSS Engine File Editing & 3D Meshing Challenge

AIM: To study the starter file and Enginefile using RADIOSS profile Change the parameters according to the requirement in starter file and Enginefile. creating Tetra mesh on housing component Hexa mesh on Arm Bracket OBJECTIVE 1. Check the material properties of the rail component and calculate the speed of sound…

03 Aug 2021 06:41 PM IST

Assignment 3-2D Element Formulation Challenge

objective: 1.Using the crash beam file from the previous assignment, change the run time to 55 ms. 2. Change the number of animation steps during simulation to a minimum of 25 and maximum of 60. 3. Run the base simulation without any modification to element properties. 4. At the end of the simulation, do the…

13 Aug 2021 05:41 PM IST

Assignment 4-RADIOSS Material Laws Challenge

Objective: Compare 7 cases as discussed in last 3 slides, in a tabulated format on the basis of: 1. Total number of cycles, Energy error, mass error and simulation time.2. Notice the animation of all 5 and describe the animations in brief on thebasis of whether the elements are being deleted or cracked.3. Plot energies…

07 Sep 2021 08:26 AM IST

Assignment 5-RADIOSS Interfaces & Study of Effect of Notches Challenge

OBJECTIVE: Create the mesh for bumper assembly,mesh size should be 6mm. Run the crash tube model as it is. Change the Inacti=6 and run. Create the type 11 contact and run. Remove both notches and remove boundary condition on rigid body node then run. Create a new notch in the middle ,select the whole section…

20 Sep 2021 09:32 AM IST

Assignment 6-Frontal Crash Simulation Challenge

OBJECTIVE: Frontal crash-BIW Check unit system and either follow[Mg mm s] or [Kg mm ms]. Create appropriate interface ,friction 0.2 and recommended parameters. Make sure of no penetrations and intersection. Correct rigid bodies if any issues. Create rigid wall with friction 0.1. Compare the model weight with the full scale…

27 Sep 2021 11:02 AM IST

Assignment 7-Side Pole Crash Simulation Challenge

OBJECTIVE: Check unit system and either follow [Mg mm s] or [Kg mm ms]. Create appropriate interface ,friction 0.2 and recommended parameters. Make sure of no penetration and intersections. Create rigid wall with friction 0.1 as per referance model. Compare the model weight with the referance model and use added masses…

28 Sep 2021 06:28 PM IST

Week 1 Stress Concentration on a Plate with hole

Objective: Case :1 Design a plate with a hole model similar to what we worked in the class, but with increased thickness.Determine the maximum deformation and stress developed in the model. Plate dimensions: Length=300mmHeight=120mmThickness=30mmCircular Hole at the center:Diameter=60mm Case 2: smaller holes 90mm away…

18 Oct 2021 05:50 PM IST

Week 1 Spur Gear Challenge

Objective 1: Case 1: Using Cast Iron(ductile) as a material, carry out a static structural analysis to find out Equivalent stress, Total deformation and Stress intensity(Learn about what stress intensity is). Find location for possible fracture Case 2: Using Cast Steel as material,…

22 Oct 2021 09:49 AM IST

Week 2 Railwheel and Track

Objective: Perform a static structural analysis on the Railwheel and Track setup and Case 1: Multiply the bearing load by 5 times and compare the results with the load of 100000 N (As done in week 2 video). Compare the Total Deformation, Equivalent stress and the life under both the loads Case 2: Implement a User defined…

01 Nov 2021 01:45 PM IST

Week 3 Sheet metal Bending challenge

OBJECTIVE: Sheet metal bending is to be performed for 3 different materials mentioned below. Variation of certain settings is also to be performed and your conclusions are to be added to the report Note: Please read the instructions carefully Run the analysis for the material : Case 1:Aluminium Alloy 1199( mentioned in…

17 Nov 2021 09:16 AM IST

Week 4- Rolling operation

Objective: For this challenge, we will have to simulate the rolling operation on a workpiece made of copper. Increase the length of the workpiece by 60mm and decrease its size on both sides by 8mm. Run the simulation for 14 steps . Ensure that the edge of the workpiece is displaced by 90mm. Find out the Equivalent…

17 Nov 2021 05:45 PM IST

Week 5 Sphere pressing on a plate

Objective: For this challenge, perform the analysis to simulate a sphere pressing on a plate. Use Structural steel for both sphere and plate but the material of the plate must be Non Linear. Press the sphere onto plate 4mm downwards and retract it. Procedure: we need to add structural steel and structural steel non…

03 Dec 2021 06:22 PM IST

Week 5 Bending of iPhone

objective:For this challenge, simulate the bending of iPhone as per the given cases belowCase 1: Simulate the model as it is given in the videoCase 2: Move the bottom fingers from their defined position to the given position X= 22.5mm & Z= 10mm and obtain the results for the simulation. Also define the S-N curve for…

15 Dec 2021 05:41 PM IST

Week 7-Long Piston With Cam

Objective: For this challenge we will have to perform a transient analysis on a piston and cam mechanism model that has been provided to you. You need to run the analysis with Frictionless contact, Frictional with 0.1 and 0.2 as the frictional contact for a total of 3 cases. Find out the Equivalent Stress, Directional…

17 Dec 2021 06:23 PM IST

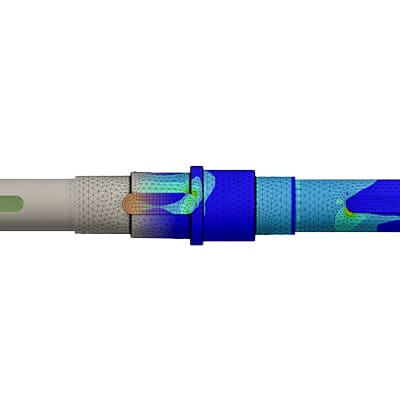

Week 8 - Universal Joint

Objective: To perform a transient structural analysis on a double universal joint with a spring using three different materials: Structural Steel, Stainless Steel and Titanium alloy(They can all be found in the General Materials section) The three materials must be used on the joint with the springs alone. Use a refined…

19 Dec 2021 01:57 PM IST

Week 8 Worm Gear Challenge

Objective: To perform a transient structural analysis on a worm gear assembly. For the academic version, you need to cut the gear by half so as to bring the model within limits. For the challenge, you have to rotate the worm so as to get to almost end of the half cut and get results for Equivalent stress, Equivalent elastic…

20 Dec 2021 08:22 AM IST

Week 9 Machining with Planer Challenge

Objective: To perform an explicit dynamics simulation to find out the Equivalent Stress, Total Deformation and also insert a User defined result to calculate the temperature of the body. need to perform this for 2 cases. One will be with a cutting velocity of 20000mm/s and the other will be with a cutting velocity of 15000mm/s…

21 Dec 2021 07:46 AM IST

Week 9 Tension and Torsion test challenge

Objective: To perform the tension and torsion test on the specimen provided below the video corresponding to the challenge. For the tension test, displace one end of the specimen to 18mm while keeping the other fixed. You will need to find out the total deformation, equivalent stress and temperature of the specimen For…

21 Dec 2021 09:06 AM IST

Week 10 Bullet penetrating a Bucket Challenge

OBJECTIVE: To simulate a bullet penetrating into a bucket. You will need to use 3 different non linear materials for the bucket and analyse their behaviour for the same velocity of bullet. Apply the conditions for bullet as mentioned in the video itself. Attach an animation to show the behaviour in the three cases. procedure:…

23 Dec 2021 07:23 AM IST

Week 3 Verification of Weld Joints

Objective: Simulate three different types of welding using three different weld materials Weld Material used: Case 1. Stainless Steel: In this case, the material of the plates must also be the same. Use Stainless steel for both weldments and plates. No need to add flux to the weldments. Case 2. Aluminium Alloy:The…

23 Dec 2021 09:14 AM IST

Week 11 Car Crash simulation

Objective: To perform a parametric study using 3 different values of thickness for the car body. You need to apply the same conditions as mentioned in the video that corresponds to this challenge.Analyse the total deformation and Equivalent stresses acting on the model. Procedure: add stainless steel material to the library…

24 Dec 2021 09:27 AM IST

Week 4 -Wire Bending Challenge

Objective: For this challenge, we will have to perform an analysis to simulate the bending of a wire in ANSYS. we will have to use Copper Alloy (Non Linear), Aluminium Alloy (Non Linear) and Magnesium Alloy ( Non Linear) for the wire alone. You need to find out the Equivalent stress and Equivalent strain on the wire alone.…

25 Dec 2021 07:23 AM IST

Week 2 Bevel Gear Challenge

OBJECTIVE:1)Write a few words on what a grid dependency test is and its use.2)Perform a grid dependency test for the Bevel gear simulation for mesh sizes of 6,5 and 4 mm3) Solve for Von-Mises stress, Equivalent elastic strain and Total Deformation using the previously mentioned mesh sizes.4) Present your findings in an…

27 Dec 2021 09:03 AM IST

Week - 1 - Consistency of Units

OBJECTIVE: Value of the following measurements are given as follows: MASS 1kgLENGTH 1mTIME 1sFORCE 1NSTRESS 1PaENERGY 1NmDENSITY 1Kg/m3YOUNG'S Modulus 210GPaVelocity 56.33KMPHGRAVITY 9.8m/s2 Now, here are a few system of units: Kg cm ms Kg cm s gm mm ms kg m s g cm s g cm us g mm s ton mm s slug ft s kg mm s…

24 Feb 2022 03:18 PM IST

Week - 2 - Explicit and Implicit Analysis

Explicit And Implicit Analysis F(u)=u^3+9u^2+4u ---- (1) solve using both Explicit and implicit methods (have a tolerance of 10^-2) stiffness k(u)=dF/du= 3u^2+18u+4 ---- (2) Explicit Analysis: In Explicit analysis mostly dynamic analysis and nodal accelerations are…

12 Mar 2022 09:03 AM IST

3 Course Certificates

HyperMesh for FEA Plastic and Sheet Metal Applications

Crashworthiness Analysis using HyperMesh and Radioss

Introduction to Structural Analysis using ANSYS Workbench

2 Workshop Certificates

Introduction to Airbag folding and simulation using Ls-Dyna

Academic Qualification

M.E

Osmania University Hyderabad

08 Sep 2017 - 10 Oct 2019

12th

Government polytechnic

25 Jun 2011 - 18 Jun 2014

10th

sri vidya vidyalayam

08 Jun 2009 - 11 May 2010

Here are the courses that I have enrolled

Similar Profiles

Ladder of success cannot be climbed with hands in pocket.

The Future in Motion

The future in motion

Passionate to learn